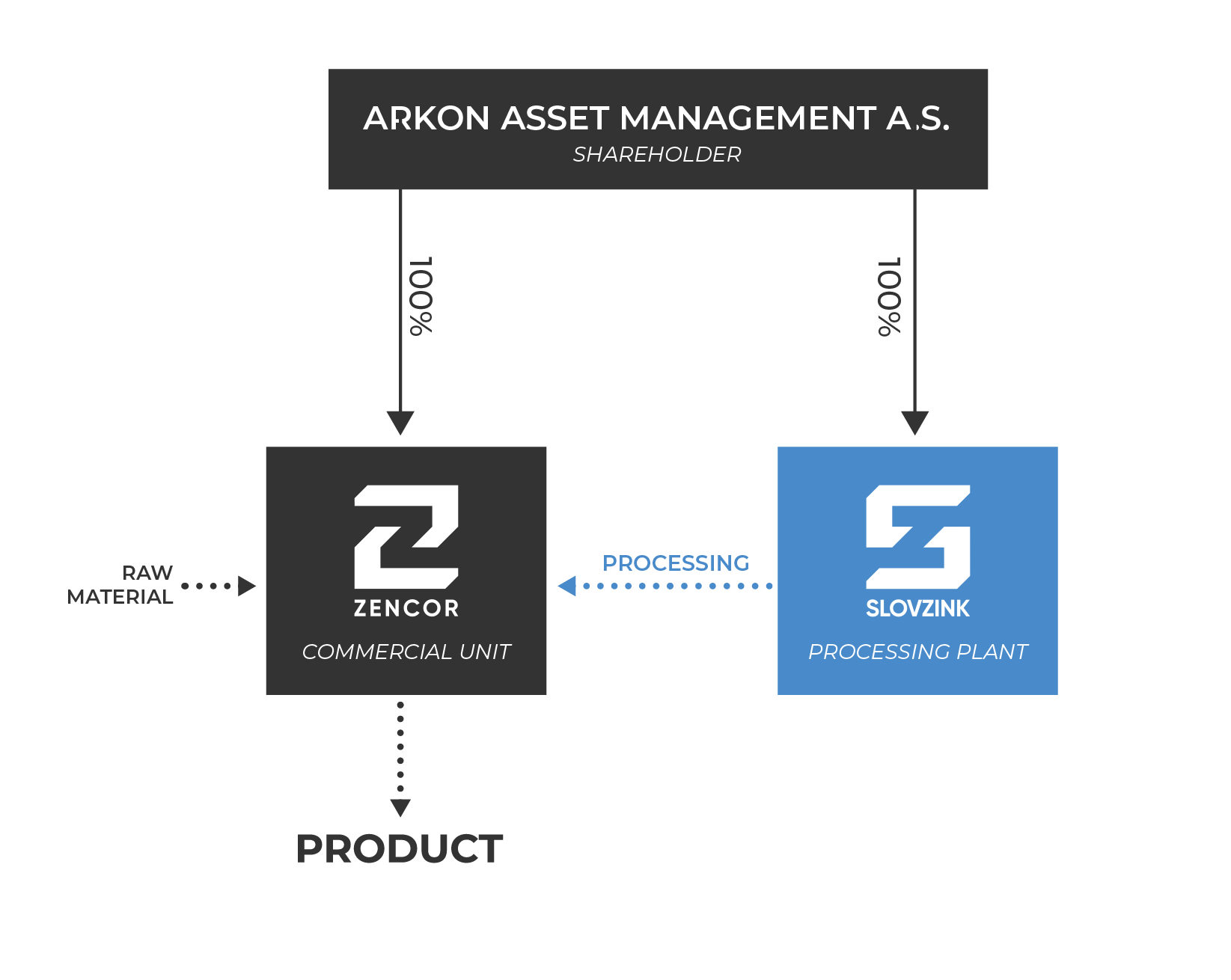

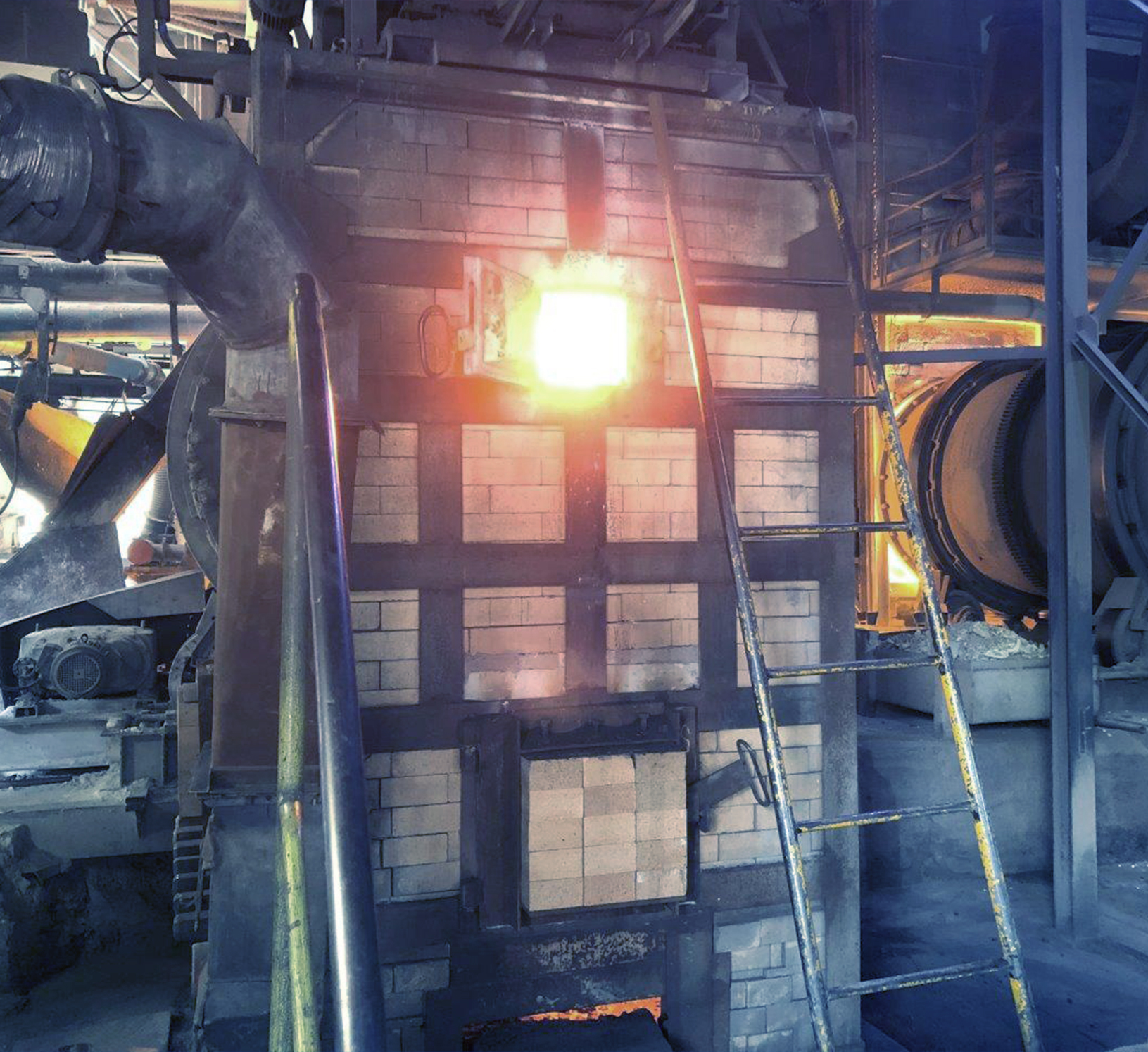

The first production plant at our site was established in 1863 by baron Schenk a member of the Coburg's family. Production of zinc oxide with a daily capacity of 2400 kg started in 1909. Zinc oxide was then exported to Sweden, Yugoslavia Turkey and India. Between 1958 and 1989 our plant was a part of the state chemical group Barvy Laky and supplied mainly COMECON countries. After the split of Czechoslovakia the plant continued separately under the name Slovlak operating two divisions, production of zinc oxide and production of paints and coatings. It was privatized in 1999 when it received its current name SlovZink. In 2008 the paints and coatings division was detached to a separate a company which has been continuing under the original brand name Slovlak. Since 2013 SlovZink has been diverted solely on production activities, all commercial activities have been relinquished to the newly established exclusive partner Zencor, and then in 2019 transferred to its successor Zencor processing.